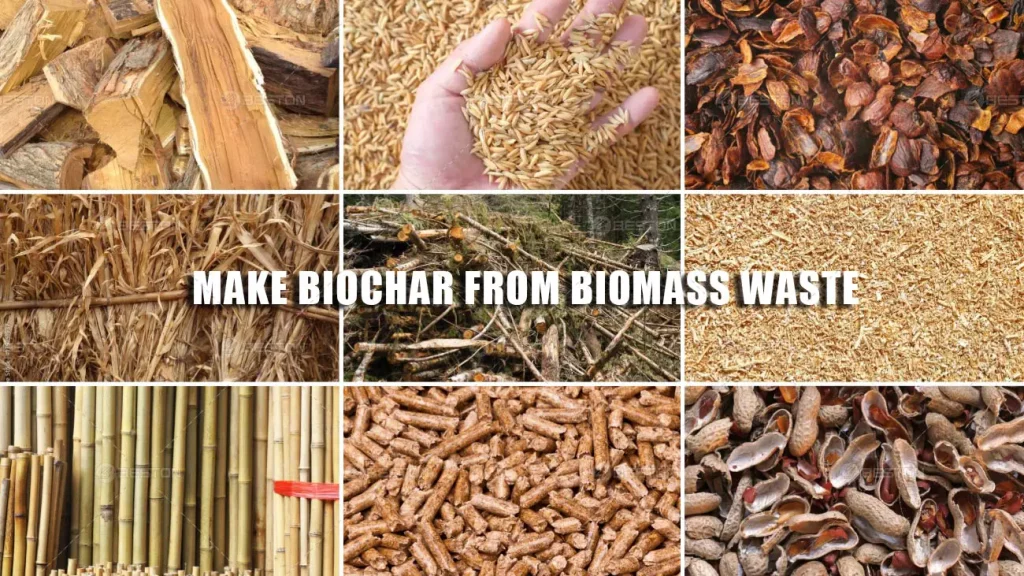

The flexibility of biochar production allows for innovation and further research to discover new feedstocks, creating a promising future for biochar in addressing global environmental challenges. Here, we will explore three key representatives of raw materials used in biochar manufacture: agricultural waste, forest and wood waste, and shell biomass waste.

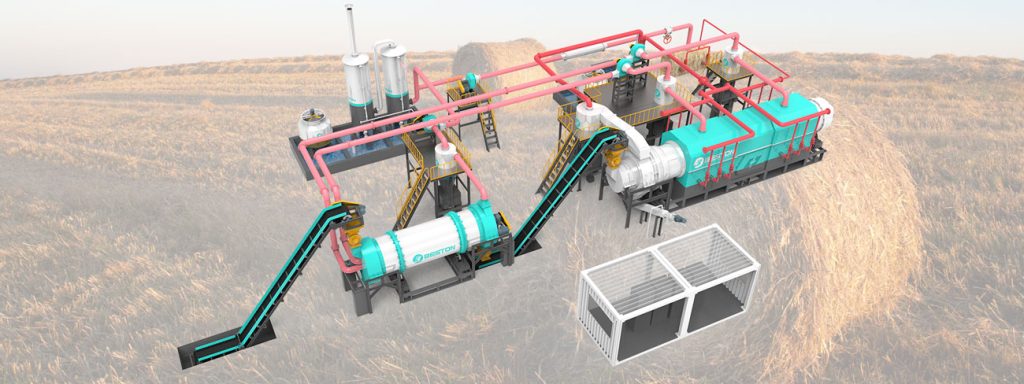

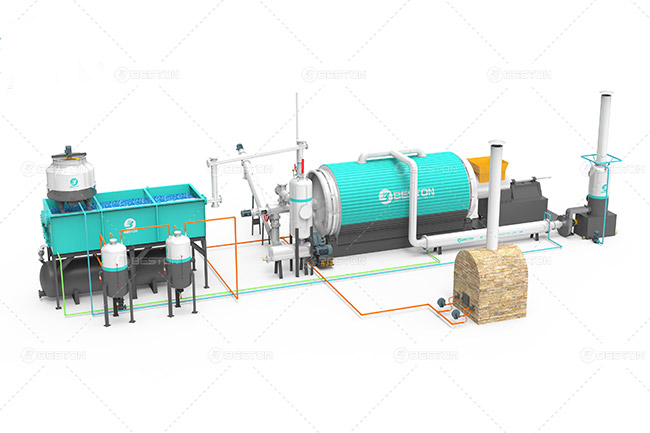

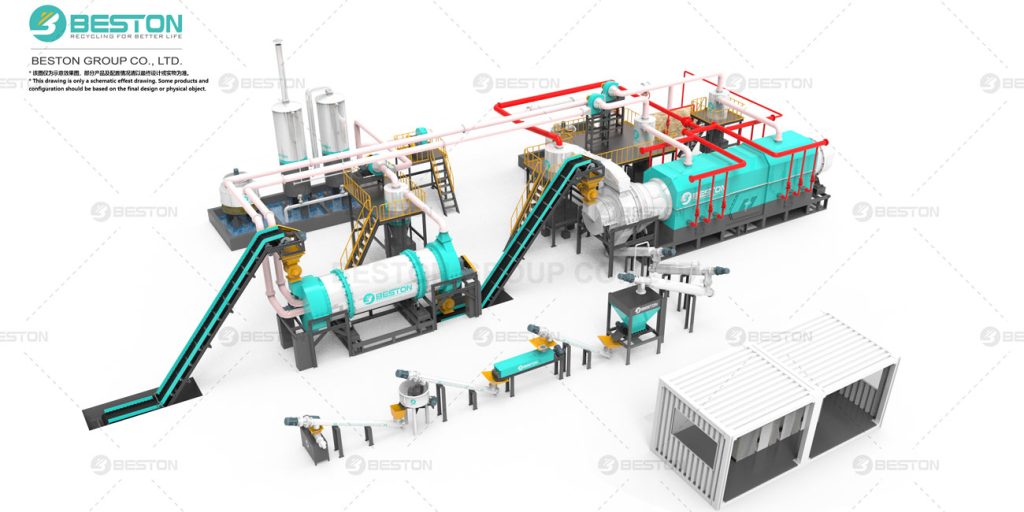

Biochar is a carbon-rich material produced through the pyrolysis of various organic materials, and it has numerous applications, including soil enhancement, carbon sequestration, and waste management. The production of biochar involves the heating of raw materials in a biochar pyrolysis machine under low-oxygen conditions. Different raw materials can be used in this process, and each offers unique characteristics.

1. Agricultural Waste

Agricultural waste, including rice husks, corn stalks, and other crop residues, plays a significant role in biochar production. One of the most common agricultural by-products used for biochar manufacture is rice husk. The rice husk charcoal machine is specifically designed to convert rice husks into biochar. This material is rich in silica and, when converted into biochar, can improve soil structure, moisture retention, and nutrient availability. Rice husks are abundant in many countries, making them an ideal and sustainable raw material for biochar production. Additionally, using agricultural waste helps reduce the environmental burden associated with the disposal of crop residues.

2. Forest and Wood Waste

Forest and wood waste, such as sawdust, tree bark, and wood chips, are other prominent raw materials used for biochar production. These materials are rich in carbon and can be efficiently processed in a wood charcoal machine. The pyrolysis of forest and wood waste produces high-quality biochar that can be used to enhance soil health, improve water retention, and increase agricultural productivity. Additionally, the use of wood waste helps mitigate the negative environmental impact of deforestation and logging, as it provides a sustainable way to repurpose materials that might otherwise be left to decay or burned.

3. Shell Biomass Waste

Shell biomass waste, such as palm shells, coconut shells, and other nut shells, is another valuable raw material for biochar manufacture. Palm shell biomass waste, in particular, can be processed using a palm shell charcoal machine. These shells are rich in carbon and have a hard, dense structure, making them an excellent source for producing biochar. The resulting biochar from palm shells has a high surface area and can be utilized in various applications, including water filtration and soil amendment. The use of shell biomass waste not only provides a sustainable method for biochar production but also helps manage the waste from the palm oil industry, which is one of the world’s largest agricultural sectors.

Conclusion

In conclusion, the choice of raw materials for biochar production is crucial in determining the final product’s quality and its potential applications. Agricultural waste, forest and wood waste, and shell biomass waste are among the most widely used materials, each offering distinct benefits for the production of biochar. Whether using a rice husk charcoal machine, wood charcoal machine, or palm shell charcoal machine, these raw materials contribute to sustainable waste management, environmental protection, and soil improvement. As demand for biochar grows, the use of these diverse raw materials will continue to play a vital role in supporting a sustainable and circular economy.